|

| Atlas Coal Mine National Historic Site |

It’s mid morning when we cross the Red Deer River and arrive at Atlas Coal Mine. Backdropped by badlands, the tall, wooden tipple dominates the scene, but there’s literally more beneath the surface. After climbing the 7+ storey tipple, and touring the mine site by train, we will venture into the hillside. It’s going to be an amazing journey back in time with real stories of real people!

Disclosure: Atlas Coal Mine generously hosted me and my family, but all words and opinions are my own!

Train Ride (25 minutes)

|

| Atlas Coal Mine Train Tour, East Coulee |

The girls laugh as their coal car bumps to a stop behind Linda, the 90 year old battery-powered engine. Our guide, Jessica, is telling us about trapper boys, the youngest workers at the mine. Kids aged eight and up (four in Europe!) were responsible for opening the trap doors to mine entrances to allow oxygen in and let coal cars out. Sometimes they were chained to the door so they wouldn’t leave during their shift. My kids happily volunteer to open the gates, knowing they won’t be stuck there for 12 hours like a miner’s child. As they clamber back in, Jessica starts Linda up again and segues into a colorful tale of rum running.

Over the course of the tour, we learn about braking, switching lines, how much coal a coal car could carry, how many cars a pony could pull, and how to trick a smart pony into pulling more.

Fun fact: Between the 139 mines in the area, at the peak of the Drumheller mining industry, there were 1.5 million boxcars; enough to go around the world!

Processing Plant Tour (45 minutes)

|

| Exploring the Atlas Coal Mine Tipple |

Amelia meets us at the Mine Office, to pay our wages before taking us to the tipple. With the biggest paycheque, I am not a tipple worker and thank goodness for that! Also known as the coal sorting and loading machine, “the tipple was the worst place to work” in the mine for its poor working conditions. To add insult to injury, it paid the least too. Imagine working in a drafty, noisy building through the cold, Alberta winters with no heat, ear protection, or masks. Hearing loss, black lung, and missing fingers were occupational hazards for tipple workers.

We get a taste of hiring and payroll practices from the ’30s, then visit the long locked-up manager’s office. Rumor has it, the ghosts of Dr. Omer Patrick, President of Atlas Coal Mine and Johnnie Vasco, pit boy have been seen leaning against the safe. So if anything odd happens while you’re there – “untied shoelaces, [someone] gives you a push” – blame the specters.

|

| Miya holds a big lump of Wildfire coal. |

Next, we head into Canada’s last wooden coal tipple. Over seven stories tall, it is criss-crossed by shaker plates that sort the coal into different sizes. Coal then travels down size-specific chutes to boxcars waiting below. Amelia tells us, “65 million tons of coal were mined in 73 years from this valley” (from 139 mines). Apparently there’s still enough coal in these hills to heat Canada for 100 years! She reveals the secret of Wildfire Coal’s marketing success and passes around a large chunk of wildfire coal before we head down.

|

| Canada’s last tipple – at Atlas Coal Mine National Historic Site |

Fun fact: Did you know that coal-dust covered miners were recognized by their voices at payday?

Mine Portal Hike (1 hour 15 minutes, age 6 & up)

|

| Locker Room, Atlas Coal Mine – clothes were hung high to keep them clean |

On the Mine Portal Hike, we will learn about equipment the miners used, how they got to work, what hazards they faced on a day to day basis – and of course, we go in the tunnel too. Aaron first shows us how the skyhook lockers work, then lets us take a peek at the showers. As our group of twelve piles in, we wonder how chaotic shift changes were. You could fit a few more people, but not 12 times as many! When Atlas Mine No. 3 was in operation, there were 150 guys on one shift!

|

| Mini Miner in the tunnel at Atlas Coal Mine |

After a cool carbide (acetylene gas) lamp demo, we don helmets and follow Aaron to the tunnel. For visitors’ safety, the tunnel has been reinforced with four times the supports used in the 1930s, but the tunnel height and technology are the same. Salt crystals sparkle on the notched logs along the tunnel walls and the further we go, the quieter it gets.

|

| Looking down on the tipple from the mine entrance |

Miners worked eight hours a day shovelling coal, and were paid 70 cents a ton (907 kg / 2000 lbs). While most miners shovelled 8-10 tons a day, legendary Steamshovel Pete “shovelled 12 sometimes 14 tons a day.” Aaron tells the tale of a sneaky miner who tried to cheat Pete by putting his brass check (ID tag) on Pete’s boxcart. Spoiler alert: it ended badly for the thief… but no one died.

Fun fact: New employees were often sent for a ride on the conveyor belt as a hazing ritual. They had to figure out how to get off before the end of the line!

Other Tours & Special Events

Atlas Coal Mine also offers a Junkyard Archaeology Tour (60 minutes). For more information, visit Atlas Coal Museum National Historic Site | Tours.

|

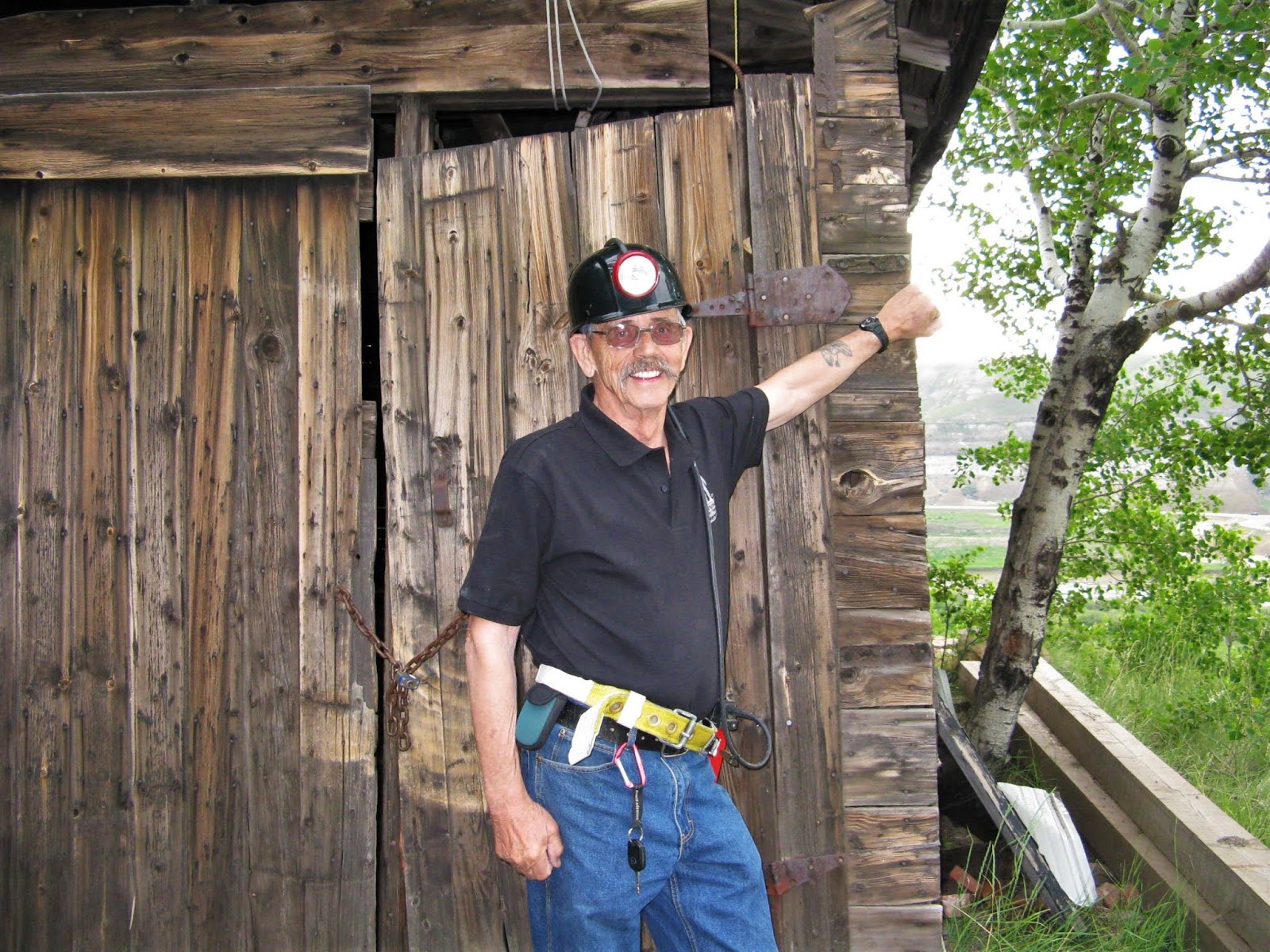

| Meet Bob Moffatt, fifth generation coal miner and hear what it was like to work in the mine. Image credit: Atlas Coal Mine National Historic Site |

The Mine and Dine immersive experience is offered in partnership with East Coulee School Museum by appointment. Suit up for a (short) day at the mine, make your own brass tag, light and wear a carbide lamp, perform a mine rescue, and get paid. Next stop is East Coulee School Museum where you make noodles from scratch and enjoy a family-style Hungarian meal. Minimum group size: 12. Read more at East Coulee School Museum.

Know Before You Go

Atlas Coal Mine is a National Historic Site, so please stay on trails and do not touch or take artifacts.

Tour times must be booked online in advance! If travelling with younger children, we recommend taking a break after one or two tours. Explore some of the old buildings, walk the interpretive trail, or have a picnic.

Wear closed-toe footwear (no sandals or flip flops) with good soles as you’ll be walking a lot for the tipple and tunnel tours. There are 200 stairs on the way back from the mine!

Bring water, sunscreen, and bug spray just in case. These items are available from the store if you forget. There’s also ice cream!

|

| Pin me! |